This is a Website Demo of the exact site we install for you

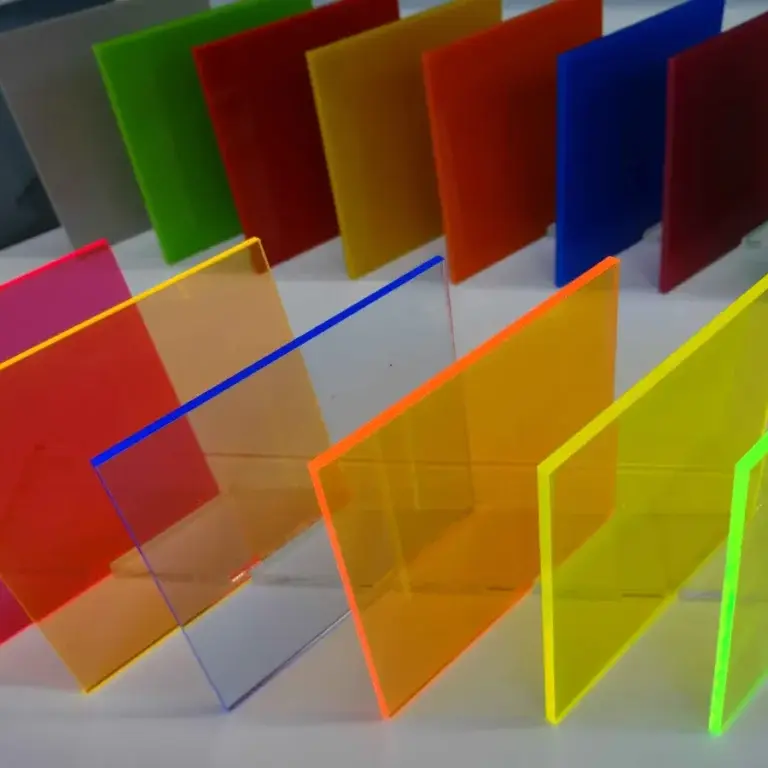

Acrylic

(Polymethyl Methacrylate, PMMA)

Description: Acrylic is a transparent thermoplastic often used as a lightweight and shatter-resistant alternative to glass. Properties: High clarity(crystal-clear appearance), excellent weather resistance, good impact resistance (though less than polycarbonate), and easy to fabricate.

Uses: Signage, display cases, windows, aquariums, and lighting.

Polycarbonate

(PC)

Description: Polycarbonate is a durable, impact-resistant thermoplastic that is known for its high strength and transparency.

Properties: Extremely high impact resistance, good optical clarity, heat resistance, and flame retardancy.

Uses: Safety goggles, bulletproof glass, greenhouse panels, and electronic components

PETG

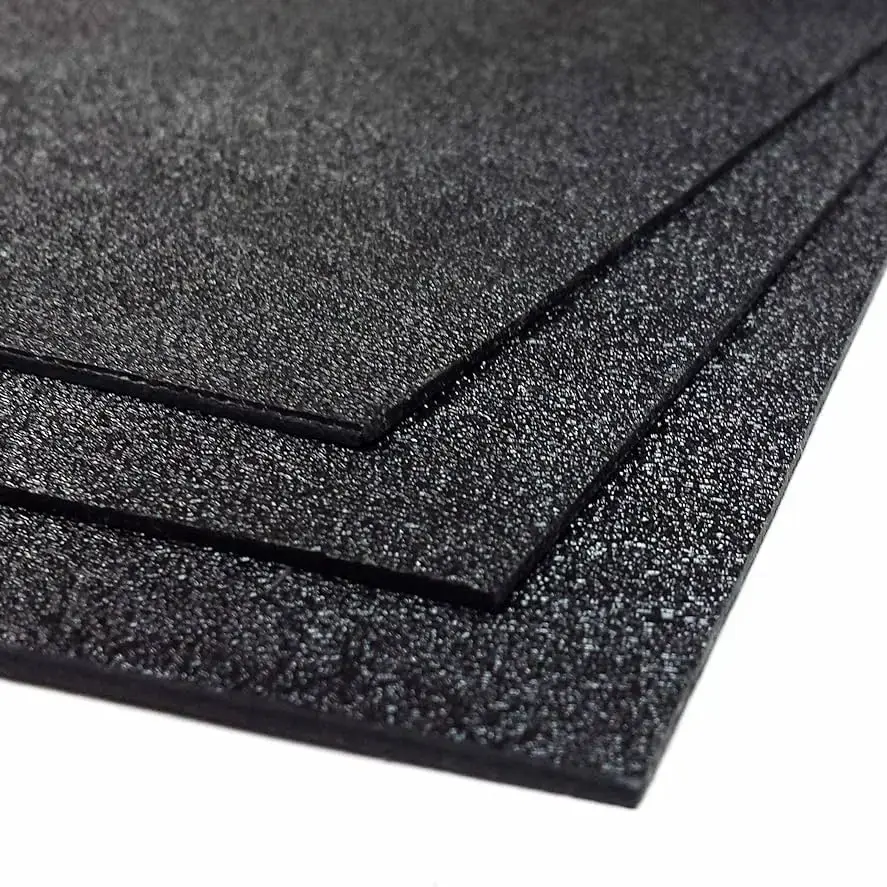

Expanded PVC

(Polyvinyl Chloride)

Description: PVC is a versatile thermoplastic polymer widely used in construction and industrial applications due to its durability, chemical resistance, and ease of fabrication. More specifically, expanded PVC is a lightweight, rigid form of PVC with a fine, closed-cell structure, e.g. Sintra and Komatex

Properties: Lightweight, good impact resistance, easy to cut and shape, good insulation properties, and flame retardant.

Uses: Signs, displays, POP exhibits, and indoor/outdoor applications(where a lightweight, rigid material is advantageous).

HDPE

(High-Density Polyethylene)

Description: HDPE is a strong, durable thermoplastic with a high strength-to-density ratio.

Properties: High impact resistance, chemical resistance, low moisture absorption, and good electrical insulation.

Uses: Piping, plastic bottles, geomembranes, and cutting boards.

ABS

(Acrylonitrile Butadiene Styrene)

Description: ABS is a tough, rigid thermoplastic with high impact resistance and good mechanical properties. Properties: High impact resistance, good heat resistance, easy to mold, and cost-effective.

Uses: Automotive parts, electronic housings, LEGO bricks, and consumer products.