This is a Website Demo of the exact site we install for you

Custom Plastic Fabrication – Your One-Stop Provider for Plexiglass, Acrylic & More

If you’re looking to create custom solutions using plastic for commercial, architectural, or industrial purposes, custom plastic fabrication is leading the way. From freestanding acrylic displays to formed plexiglass barriers, businesses in Las Vegas and beyond have relied on skilled fabrication to make their imagination a reality.

At Welch Plastics, we specialize in custom plastic fabrication from a variety of plastics, such as acrylic, plexiglass, and ABS in many forms. Whether you are a retail shop looking for some custom displays, a medical office looking for protective barriers, or a design house looking for custom sculptural acrylic components, Welch Plastics can help transform your ideas into functional and attractive products.

In this detailed overview, we’ll take a look at everything you need to know about plastic manufacturing, including materials, methods, advantages, and why Welch Plastics is your one-stop plastic manufacturer in Las Vegas.

What is Custom Plastic Fabrication?

Custom plastic fabrication is the creation of products or parts from plastic materials according to specifications from a customer. Custom fabrication is commonly used in:

- Architecture & interior design

- Retail merchandising

- Industrial equipment

- Health care environments

- Event & exhibitions displays

Our process usually starts with an idea, sketch, or CAD file. From there, we will build tools and utilize processes including CNC machining, laser cutting, thermoforming, or injection molding to produce a standardized product.

💡 Did you know? Hand fabrication techniques (chemical bonding, sanding, and polishing) are best suited for a low-volume, high-quality custom job with unique dimensions and finishes.

Examples of Custom Plastic Fabrication in the Real World

We have been involved in work across multiple industries–from national brands to high-end resorts on the Las Vegas Strip. Here are just a few applications that we have found to be effective for custom plastic fabrication:

Retail Displays

- Clear acrylic shelving

- Illuminated plexiglass signage

- POP display stands

Medical and Healthcare Facilities

- Acrylic sneeze guards

- Sterilization trays

- Instrument enclosures

Industrial and mechanical

- ABS plastic enclosures

- Custom machine guards

- Polycarbonate cover guards

Architectural and Interior Design

- Decorative acrylic panels

- Light diffusers

- Custom event installations

Branding and Signage

- Dimensional letter signage

- Wall-mounted logos

- Etched plastic name plates

(David hand fabricating circular pedestals made from 3/8” thick clear acrylic for an event company)

Materials Commonly Used in Custom Plastic Fabrication

Choosing the right plastic material is critical to achieving its functionality, aesthetics, and longevity. We have great experience at Welch Plastics and are happy to share our knowledge on the best plastic material for your application.

✅ Acrylic (PMMA)

- Lightweight, optically clear, impact resistant

- Great for display cases, signs, and sneeze guards

- Now offered in a range of colors and surface textures.

✅ Plexiglass

- Brand name and is predominantly referred to as acrylic

- Great UV resilience

- In contrast to acrylic, used primarily for aquarium applications, windows, or as barriers.

✅ Polycarbonate (PC)

- Stronger than acrylic and has greater impact resistance

- Great options for guards and other safety barriers

✅ ABS (Acrylonitrile butadiene styrene)

- Good strength and longevity

- Used most commonly for enclosures and automotive and consumer electronics components.

✅ PVC (polyvinyl chloride)

- Good weather-resistant and chemical-resistant

- Used most commonly for piping, signage, and applications that are located outdoors

Fabrication Processes

Some projects lend themselves to a certain process. As a full-service plastic manufacturer based in Las Vegas, we have multiple fabrication processes to meet your needs.

1. CNC Machining

Computer-controlled allows for ultra-accurate cuts and contours. Great for :

- Mechanical components

- Precision enclosures

- Complex 3D parts

2. Laser Cutting & Engraving

Great for fine detail and sharp edges. Often used for:

- Acrylic signs

- Logo cutouts

- Custom branding

3. Thermoforming

Heated plastic sheets are shaped into molds. Applications include:

- Plastic trays

- Automotive panels

- Custom enclosures

4. Injection Molding

Best suited for high volume production. Advantages include:

- Consistency over high volume

- Fast speed of production

- Durable strength for many uses

5 Vacuum Forming

The heated plastic sheet is drawn over a mold using suction. Used for:

- Custom casings

- Lightweight packaging

- Decorative purposes

Why Choose Custom Plastic Fabrication?

Whether you want one-off for an architectural piece or several hundred for a branded display, there are good reasons to choose custom plastic fabrication.

💰 1. Cost Effective

- Material and manufacturing costs are lower than metals

- Trimming is accurate minimising waste.

⚙️ 2. Versatility in Design

- The design possibilities are endless with curves, cut-outs and multiple colours.

- Make custom sizes for unique applications.

⚡ 3. Quick Turn around

- Rapid part prototyping and very short production cycles

- Great for urgent projects or if time is of the essence for an event.

🌧️ 4. Resistant to Weather & Chemicals

- Great for outside or sterile environments.

- Durable, resistant to corrosion and harsh weather/circumstances.

♻️ 5. Custom Moldemaking Environmentally Relevant Alternatives

- Many plastics can be recycled or repurposed

- Producing in a way that minimizes scrap

Why You Should Choose Welch Plastics as Your Trusted Plastic Fabricator

🏭 Experience

Welch Plastics has been fabricating plastic products for over 20 years. Since we naturally make products more than once every day, we are able to capitalize on other business experience to certify our quality and conformity. We have in-house knowledge of using both traditional and modern approaches, and every product passes muster.

🛠️ Full service facility

From design to delivery, we offer:

- CAD design

- CNC machining, laser cutting, injection molding - in-house

- Polishing and finishing - full service facility

🧱 Material Inventory - Diversity

We carry a large stock of:

- Clear and colored acrylics

- Specialty plastics, including polycarbonate, HDPE, ABS, and expanded PVC

- Ability to create custom thicknesses and textures

📍 Local Manufacturing in Las Vegas

Welch Plastics, located in Las Vegas, Nevada, can provide a local business, contractor, or architect with rapid turnarounds. Working locally enables us to ensure timely deliveries and personal consultations when needed.

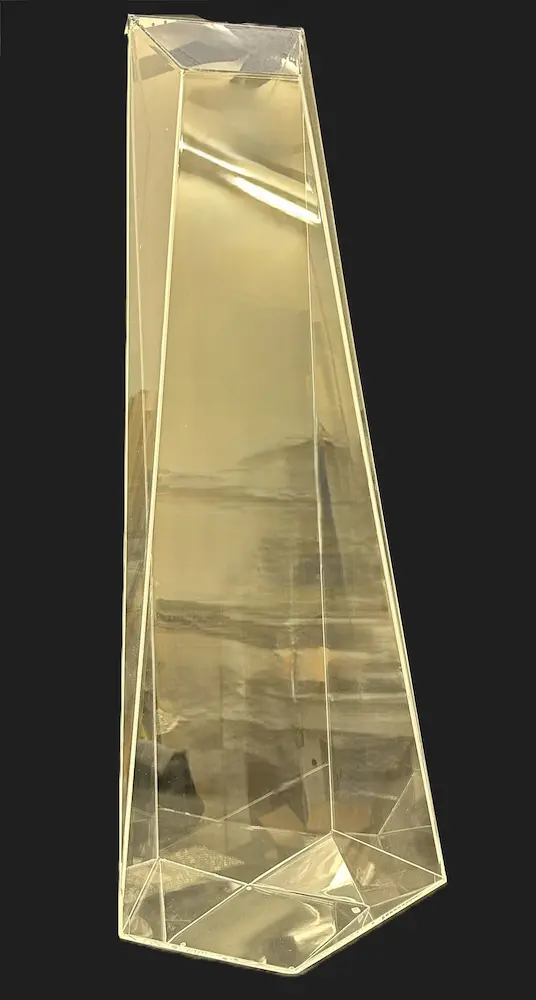

(Custom hand fabrication of a unique sculptural piece made from ¼” clear acrylic)

(Custom fabricated donut walls ordered by Fontaine Bleau Las Vegas)

We were honored to have been selected to replace these 20 large acrylic tubes at The Shops at Crystals in Las Vegas

Choosing a Plastic Fabricator

Consider these things when exploring custom plastic fabrication partners

✅ Proven portfolio - can you ask for case studies, images, or examples of products fabricated prior

✅ Range of services - can they do design and production services in-house

✅ Material knowledge - are they truly knowledgeable, or can they only suggest common plastic products for your application?

✅ Customer testimonials - look for online reviews or ask for references

✅ Responsiveness - how quickly do they reply with questions, quotes, and general correspondence? This is key with deadlines.

Conclusion

Custom plastic fabrication, build what you want for signs, retail displays, architectural/commercial installations, and industrial components, can create a valuable return in customized solutions that save time and money. Partner with a competent partner, like Welch Plastics, and you can take pride in ensuring your project will use the best accuracy, longevity, and visual lift - it is about the value.

We call on decades of experience, exercise the latest state-of-the-art technology, and create with our hands to bring your ideas to life. Whether we make acrylic pedestals, plexiglass barriers, or laser etching signs, we are your one-stop shop for everything plastic-related.

Get Your Free Quote for Your Custom Plastic

Whether you are in the market for custom plastic, we have your back!

📞 Give us a call today! (702) 240-9668

📧 Or fill out our contact form for a free quote for your consultation

We are ready to help you make your project real with L.V.s #1 plastic fabricator!

Start A Conversation

Contact us today for a no obligation quote

Where innovation meets durability – We at Welch Plastics continuously offer high-quality, precision plastic fabrication to transform your ideas into reality. Reach out to see what we can create for you.

Since 2000

Welch Plastics

Where innovation meets durability – We at Welch Plastics continuously offer high-quality, precision plastic fabrication to transform your ideas into reality.